As this is the advanced process, you can find pros and cons to lyophilization that each producer and client must be familiar with.3

Modifiable process variables and important variables to contemplate for lyophilization optimization. To obtain best drying and to maintain products composition intact, we have to avoid sample collapse, present ample time for whole drying and control the scale of forming ice crystals. Ramp and time of drying, freezing rate, and temperature must be adjusted based upon the specific Houses of various samples for example volume, construction, composition, and surface area spot.

In particular freeze-drying applications, speed is with the essence. This is where liquid nitrogen will come into Engage in. It offers a method for rapid freezing, guaranteeing which the item's composition remains intact and minimizing the scale of ice crystals.

In order to deliver a posh, lyophilized drug merchandise to sector, look no further compared to the specialists at Particle Sciences.

Sublimation is if the ice crystals go directly from a sound into a fuel without having at any time getting to be liquid, which is completed in these methods:

Our commercial facility attributes sterile lyophilization and is particularly built-in into our present development and clinical trial producing site, supplying consumers a seamless circulation from advancement via manufacturing.

, are highlighted along with suggestions to mitigate them. Ultimately, current strategy for scale-up are shared as well as future-technology PAT instruments and strategies that will impart meaningful reward about common methods for cycle progress and scale-up and/or complement the current approaches.

With many years of expertise inside the pharmaceutical industry, we know just what a great infrastructure for your cryogenic freeze dryer demands.

In the nutshell, the results of freeze-drying would not entirely lie in the machinery or the principal process. It is a holistic approach, taking into consideration every minute detail, from being familiar with the nuances of temperatures and pressures to making sure the tools and sealing processes are exceptional.

Freeze-drying demands specialized and infrequently high-priced tools that works underneath a specific temperature and strain.

The more info conditions below which the process takes position will identify the caliber of the freeze dried merchandise. Some essential facets to become regarded in the course of the freeze drying process are as follows:

Residual dampness: Even immediately after primary and secondary drying, trace quantities of dampness may perhaps continue to be inside the item. This residual humidity can adversely impression the stability and shelf lifetime of some products. So, monitoring and reducing residual dampness is imperative for ensuring products longevity.

Controlled fee freezer: the cryogenic infrastructure Cooling an item to a temperature much underneath 0 at an ideal level inside a controlled charge freezer.

Sublimation could be the linchpin from the freeze-drying process. In simpler conditions, it more info is the transformation of a substance from a reliable point out directly right into a gaseous one particular, skipping the liquid section.

Michael Oliver Then & Now!

Michael Oliver Then & Now! Monica Lewinsky Then & Now!

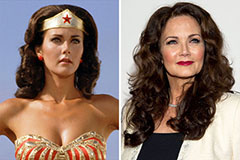

Monica Lewinsky Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Barbara Eden Then & Now!

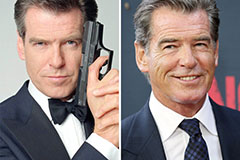

Barbara Eden Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!